| Availability: | |

|---|---|

| Quantity: | |

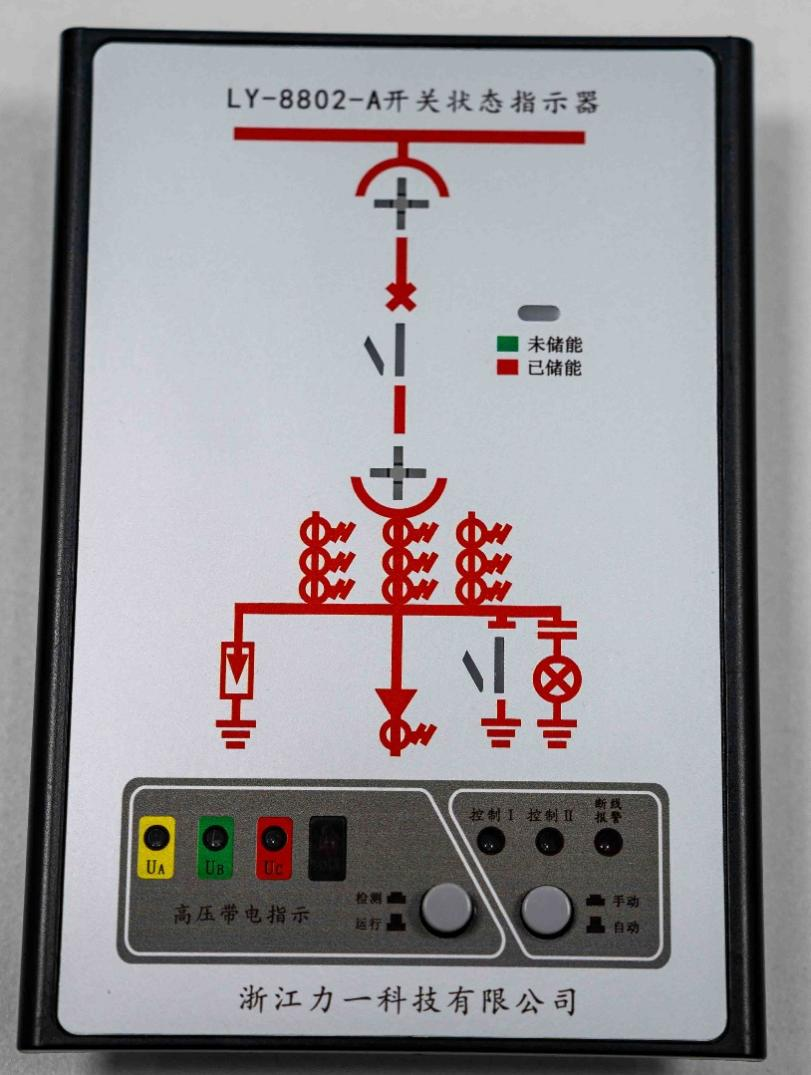

The LY-8802 Switchgear Status Indicator is a high-performance monitoring solution designed for real-time tracking of industrial switchgear status in power distribution systems. Engineered with rugged construction and intelligent sensing technology, this device provides clear visual and digital cues for switch positions, fault conditions, and environmental parameters (temperature, humidity). It withstands harsh industrial environments—including extreme temperatures, high humidity, and electromagnetic interference—while integrating seamlessly with existing switchgear panels. The LY-8802 enhances operational safety, reduces human error, and enables proactive maintenance, making it indispensable for power substations, industrial plants, and commercial buildings.

Features large, color-coded LED displays (green for “on,” red for “off”) that are easily visible in low-light or high-glare environments, enabling quick status checks.

Tracks switch positions (working/test/ground), temperature and humidity, and phase-specific live status, providing comprehensive switchgear health data.Detects faults such as overheating, sensor disconnection, and abnormal switch positions, triggering audible/visual alarms and remote notifications via RS485.

Housed in a corrosion-resistant enclosure with IP-rated protection against dust and water, meeting international standards for harsh industrial settings.

Equipped with passive normally closed locking output to prevent unauthorized switch operation, enhancing operational safety.

Operates on AC/DC 110-220V power supply, ensuring compatibility with most industrial electrical systems.

Complies with IEC255-22 standards, maintaining stable performance in electromagnetic-intensive environments (e.g., near transformers).

The LY-8802 operates within a -20℃~65℃ ambient temperature range, with ±1℃ temperature accuracy and 5%RH humidity accuracy. It features two temperature/humidity sensors, dual heating/dehumidification outputs, and RS485A/B communication ports. Key functions include live display, switch position indication, fault alarming, and locking control.

Parameter | Specification |

Ambient Temperature | -20℃ ~ 65℃ |

Measurement Accuracy | Temperature: ±1℃; Humidity: ±5%RH |

Relative Humidity | ≤95%RH (non-condensing) |

Working Power Supply | AC/DC 110V ~ 220V |

Insulation Performance | ≥100MΩ |

Dielectric Strength | ≥AC 2000V |

Communication Protocol | RS485 (RS485A/RS485B) |

Locking Output | Passive normally closed |

Heating Output | 2 channels (passive normally open) |

Anti-EMI Compliance | IEC255-22 standard |

Monitors circuit breakers and isolators in substations, enabling efficient load management and quick fault isolation.

Tracks switchgear controlling pumps, compressors, and production lines, preventing downtime from electrical failures.

Integrates with building automation systems to monitor power distribution switchgear, optimizing energy use and ensuring occupant safety.

Monitors switchgear in solar/wind power installations, ensuring safe and efficient power transfer to the grid.

Protects critical power distribution switchgear, preventing data loss from unexpected electrical disruptions.

Ensure compatibility with the switchgear’s voltage rating and structural design (e.g., withdrawable or fixed-type cabinets).

Determine required functions: live display, temperature/humidity monitoring, or dual heating outputs.

Verify the system’s power supply matches AC/DC 110-220V for stable operation.

Confirm the installation site’s temperature/humidity falls within the device’s operating range.

Ensure compatibility with the system’s RS485 communication setup for remote monitoring.

Install the device via pre-drilled holes, connect power supply (AC/DC 110-220V), and wire sensors (temperature/humidity, live display) as per the diagram.

Set alarm thresholds (e.g., temperature ≥60℃) and communication parameters via the on-device controls or software.

Check LED indicators for switch position (working/test/ground) and live status; review temperature/humidity data via remote monitoring.

Clean the enclosure and sensors quarterly; calibrate temperature/humidity measurements annually to ensure accuracy.