| Availability: | |

|---|---|

| Quantity: | |

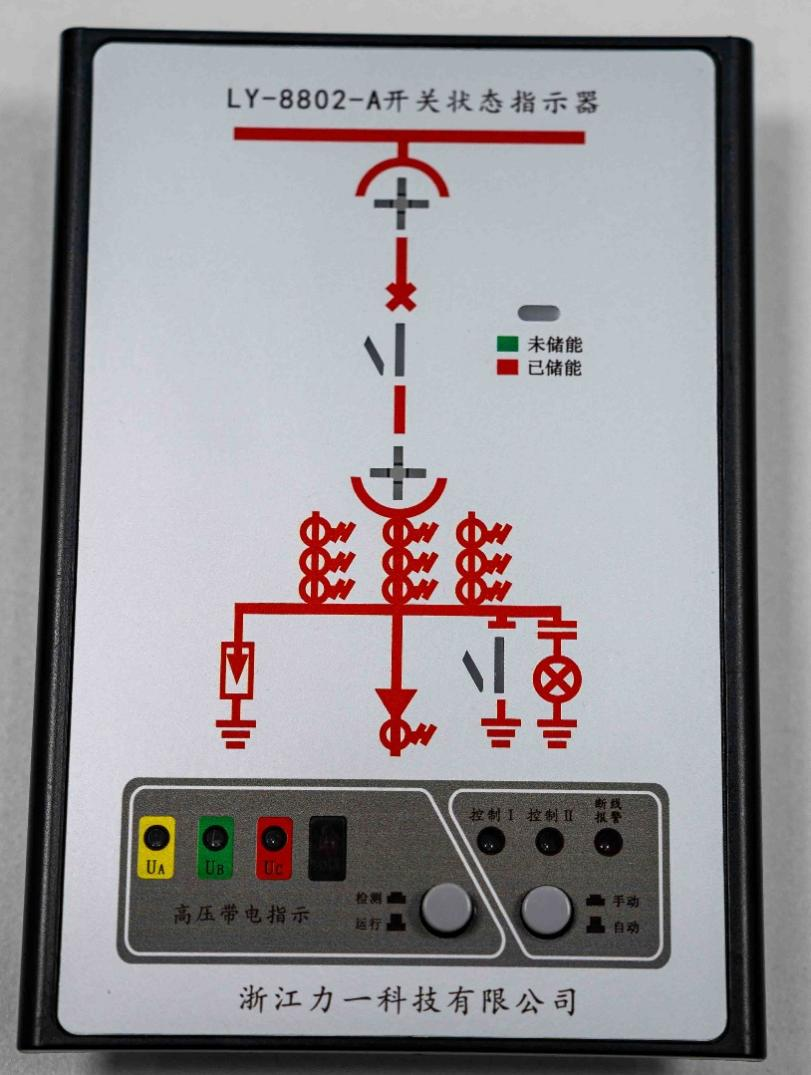

The Switchgear Status Indicator LY-8800 is a cutting-edge monitoring device engineered to redefine cabinet operational oversight. Integrating advanced LED status indication technology with an intuitive, user-centric design, this compact and robust device delivers real-time visibility into critical switch states. Whether for industrial control systems or power distribution cabinets, the LY-8800 ensures seamless performance across diverse environments, thanks to its durable construction and wide-ranging compatibility. As an indispensable tool for modern automation, it simplifies operational management while enhancing safety and efficiency—making it a top choice for engineers and facility managers worldwide.

Equipped with high-brightness red, green, and yellow LED indicator lights, the LY-8800 provides clear, customizable status cues for switch positions, energy storage, and fault alerts. The lights offer excellent visibility even in low-light industrial settings, eliminating ambiguity in operational status.

Supporting panel mounting, DIN rail mounting, and surface mounting, the device adapts effortlessly to any cabinet setup. This versatility eliminates installation constraints, ensuring quick integration into existing systems without extensive modifications.

With a broad input range of 12V to 240V AC/DC, the LY-8800 boasts exceptional multi-voltage compatibility, fitting seamlessly into diverse power systems. This flexibility reduces the need for specialized power adapters, cutting costs and simplifying inventory management.

Enabled with Ethernet and Wi-Fi connectivity, the device supports remote monitoring, allowing users to access real-time status updates and performance data from any location. This feature facilitates proactive maintenance, minimizing downtime and optimizing operational efficiency.

Featuring a modular expandability design, the LY-8800 can be easily upgraded with additional indicator modules. This adaptability ensures the device grows with evolving monitoring needs, extending its lifespan and maximizing return on investment.

Engineered for low power consumption, the LY-8800 embodies energy-efficient performance, reducing long-term operational costs while minimizing environmental impact. Its low-power design does not compromise functionality, ensuring reliable 24/7 operation.

The LY-8800 meets rigorous industrial standards, delivering precise and stable performance in harsh conditions. Below are its key technical parameters:

ambient temperature | -20℃~65℃ |

Accuracy | Temperature±1℃ humidity5%RH |

Relative humidity | ≤95%RH |

Medium strength | ≥AC2000V |

Insulating properties | ≥100MΩ |

Working power supply | AC/DC 110V~220V |

Anti-electromagnetic interference performance | Comply with IEC255-22 standard |

These specifications ensure the device’s reliability in high-interference, high-humidity industrial environments, making it suitable for critical applications.

Ideal for industrial automation facilities, the LY-8800 monitors switch status in manufacturing plants, ensuring seamless operation of production machinery and equipment. It provides instant alerts for faults, enabling quick troubleshooting to avoid production delays.

In power distribution cabinets and utility substations, the device offers vital status indication for circuit breakers, grounding positions, and energy storage. This enhances operational safety by preventing accidental operations and simplifying maintenance.

Essential for control panel monitoring in commercial and industrial applications, the LY-8800 facilitates rapid status checks and maintenance. It streamlines fault diagnosis, reducing downtime for critical systems such as HVAC and security controls.

Choose the appropriate mounting type (panel, DIN rail, or surface) based on cabinet design and available space. DIN rail mounting is recommended for standard control cabinets, while surface mounting suits custom setups.

Ensure the device’s voltage range (12V-240V AC/DC) matches your system’s power supply to avoid compatibility issues.

Determine the number of status indicators needed (e.g., switch position, energy storage, fault alerts) and select compatible expansion modules if required.

Confirm the operating environment (temperature, humidity, interference level) aligns with the device’s specifications for optimal performance.

Select the appropriate mounting position and secure the device using provided hardware.

Connect the power supply (AC/DC 110V~220V) and ensure proper grounding.

Wire sensors and control terminals according to the user manual, verifying connections for tightness.

Avoid wiring the device near high-voltage cables to reduce electromagnetic interference. Use shielded cables for sensor connections to enhance signal stability.

During voltage withstand test, disconnect the live display sensor terminals to prevent damage. Restore connections only after the test is complete.

Monitor LED indicators for real-time status updates. Use remote monitoring tools to check performance data and configure alerts for abnormal conditions.