| Availability: | |

|---|---|

| Quantity: | |

LY-W2K

Liyi

LY-W2K

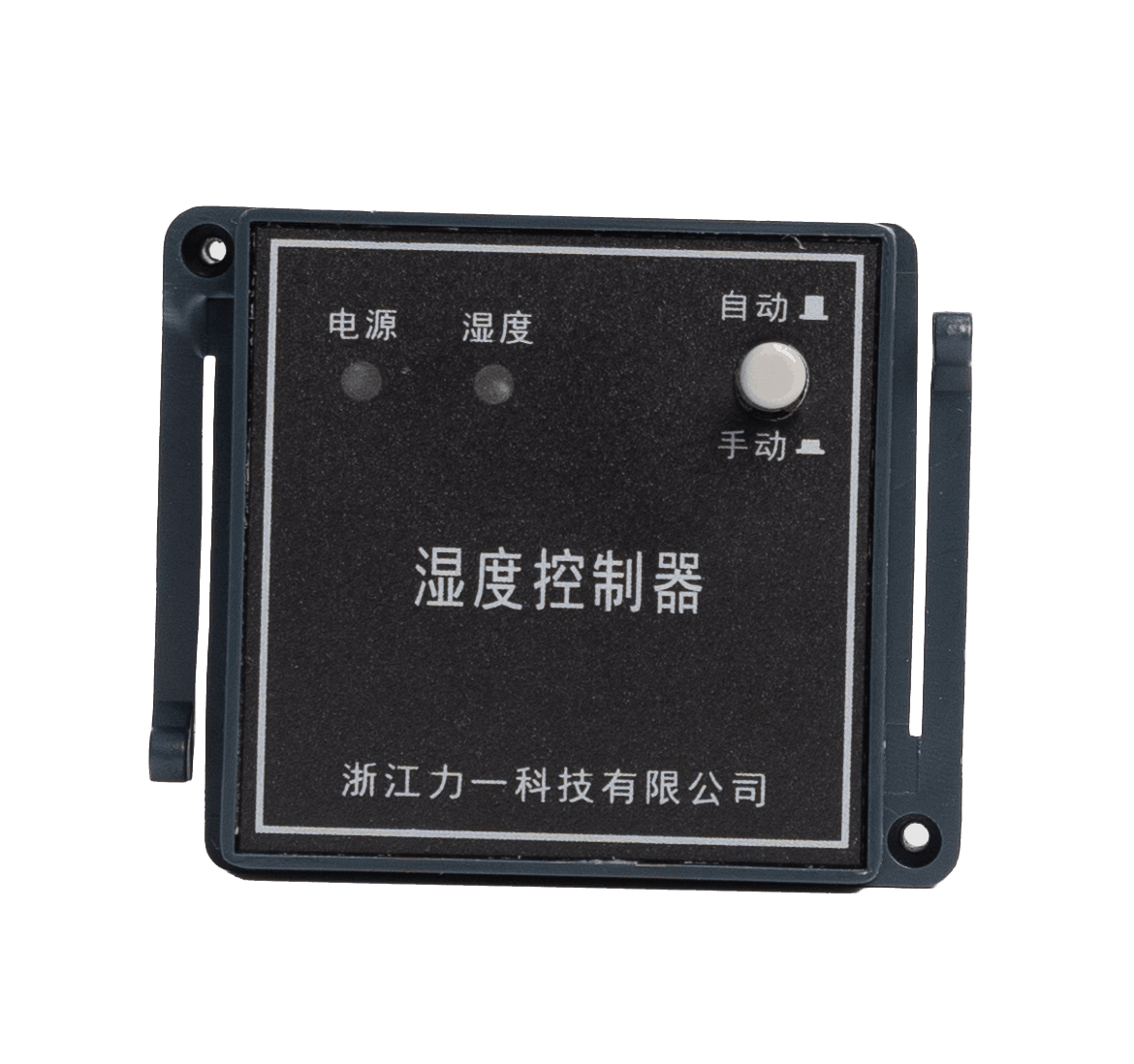

The LY-W2K heating-type conventional temperature and humidity controller is a specialized environmental regulation product launched by Zhejiang Liyi Technology Co., Ltd. , focusing on temperature heating control while providing auxiliary humidity monitoring. It is designed to solve the problem of low-temperature damage in scenarios such as cold storage, industrial processes, and pharmaceutical storage, with the core goal of maintaining a stable and precise heating environment to ensure product integrity and process continuity.

The LY-W2K offers Automatic Mode and Manual Mode for flexible application: Automatic Mode intelligently activates heating equipment when temperature drops below the preset lower limit, and stops heating when it reaches the upper limit; Manual Mode allows users to manually start/stop the heating function, suitable for emergency heating or special process requirements.

With a temperature accuracy of ±0.5℃ and a control backlash of 0~20℃, the LY-W2K can maintain the target temperature within a narrow range, avoiding overheating or insufficient heating. Its fast heating response design enables quick temperature recovery in low-temperature environments, reducing energy waste and improving efficiency.

Equipped with Dual Temperature Sensors (Sensor 1 & Sensor 2), the controller monitors temperature in real time from two points, ensuring data authenticity. If one sensor fails, the system automatically switches to the backup sensor to prevent heating interruption—a key safety feature for temperature-sensitive applications like vaccine storage. The built-in temperature alarm also alerts users promptly to abnormal temperature changes.

The intuitive user interface with clear "Power/Temperature 1/Temperature 2" indicators and simple button controls allows for easy setup without professional training. Its industrial-grade durable construction resists corrosion and temperature fluctuations, ensuring stable operation in harsh environments (operating temperature: -20℃~70℃; relative humidity ≤95%RH) for long periods.

The LY-W2K’s technical parameters are optimized for heating performance: it uses AC 220±10% 50Hz power supply, compatible with global industrial standards; the temperature control range of -9℃~99℃ covers most low-temperature heating needs; the 3A dual working voltage load capacity supports various heating devices (e.g., electric heaters, heat lamps). Its <2W low power consumption reduces operational costs.

Operating Power | AC 220±10%,50HZ |

Conditions of use | Temperature -20℃~70℃;Relative humidity≤95%RH |

span of control | Temperature -9℃~99℃;Humidity 0~99%RH |

accurate | Temperature 0.5℃;Humidity 5%RH |

Control backlash | Temperature 0~20℃;Humidity 0~20%RH |

load capacity | Double working voltage 3A |

pressure resistance | 50Hz, 1000V alternating current duration 1 min |

power consumption | <2w |

volume | 48✖48✖78mm3 |

In food cold storage, pharmaceutical cold chain warehouses, and vegetable greenhouses in cold regions, the LY-W2K provides supplementary heating to maintain the minimum safe temperature (e.g., 5℃ for fruits, 2~8℃ for vaccines), preventing freezing damage and ensuring product quality preservation.

In plastic molding, metal processing, and chemical reaction processes, the controller regulates the temperature of production equipment or materials to ensure consistent process conditions, avoiding product defects caused by temperature variations and improving production efficiency.

For temperature-sensitive drugs (e.g., insulin, biological agents) in pharmacies, hospitals, and pharmaceutical warehouses, the LY-W2K maintains a stable storage temperature, complying with national pharmaceutical storage standards and ensuring drug efficacy and safety.

In microbial culture, chemical synthesis, and material performance testing experiments, the controller provides precise and stable heating conditions, ensuring the accuracy and repeatability of experimental results, making it an indispensable tool for scientific research.

Choose the LY-W2K if your application requires active heating (not just temperature monitoring) or operates in low-temperature environments (e.g., northern industrial workshops, winter cold storage). For humidity-priority scenarios, select the LY-S2K instead.

Pair the controller with the ALE-W2K input module (designed for 2 temperature inputs) to enhance temperature signal collection accuracy and control responsiveness. Ensure the heating load power matches the controller’s 3A load capacity to avoid equipment overload.

For high-risk applications (e.g., vaccine storage, precision manufacturing), add the disconnection alarm function to receive instant alerts if heating elements or sensors fail, preventing irreversible losses caused by temperature deviations.

Power Wiring: Connect AC 220V power to terminals 6-10 (AC input) and terminal N (neutral wire); verify the "Power" indicator lights up to confirm successful connection.

Heating Load & Sensor Installation: Connect heating equipment (e.g., electric heater) to the load terminals; mount Sensor 1 and Sensor 2 near the heating target (avoid direct contact with heating elements) for accurate temperature detection.

Enter setup mode by pressing the "Auto/Manual" button; set the heating upper limit (e.g., 25℃) and lower limit (e.g., 15℃) according to application requirements.

Confirm the settings and exit setup mode; the controller will automatically activate/deactivate the heating load based on real-time temperature readings.

Sensor Calibration: Calibrate both temperature sensors every 6~12 months using a standard temperature calibrator to maintain measurement accuracy.

Load & Wiring Check: Monthly inspect the heating load connection for loose wires or overheating; clean the sensor surface to remove dust and debris affecting temperature detection.

Alarm System Test: Quarterly test the alarm function by adjusting the temperature beyond preset thresholds to ensure timely alerts for abnormal conditions.